Let’s take a dive into brake bias. Just because you have a bigger caliper, doesn’t necessarily mean that you have more stopping power. The concept of brake bias or brake balance is important to understand because it explains the importance of balancing the front and rear brake distribution under load.

Basically, if your front calipers are working too hard and the rear lifts up, you lose traction in the rear, thus braking efficiency is sacrificed and weight balance is off. You can use compression settings if you have them on double adjustable coilovers to dial this out. Suspension and braking work hand in hand with one another. As popular as big brake kits are with the E46 M3 crowd, often times we see improper brake setups especially with those who are retrofitting their calipers from other vehicle models. Here we explain the recommended brake bias for different vehicles and calipers.

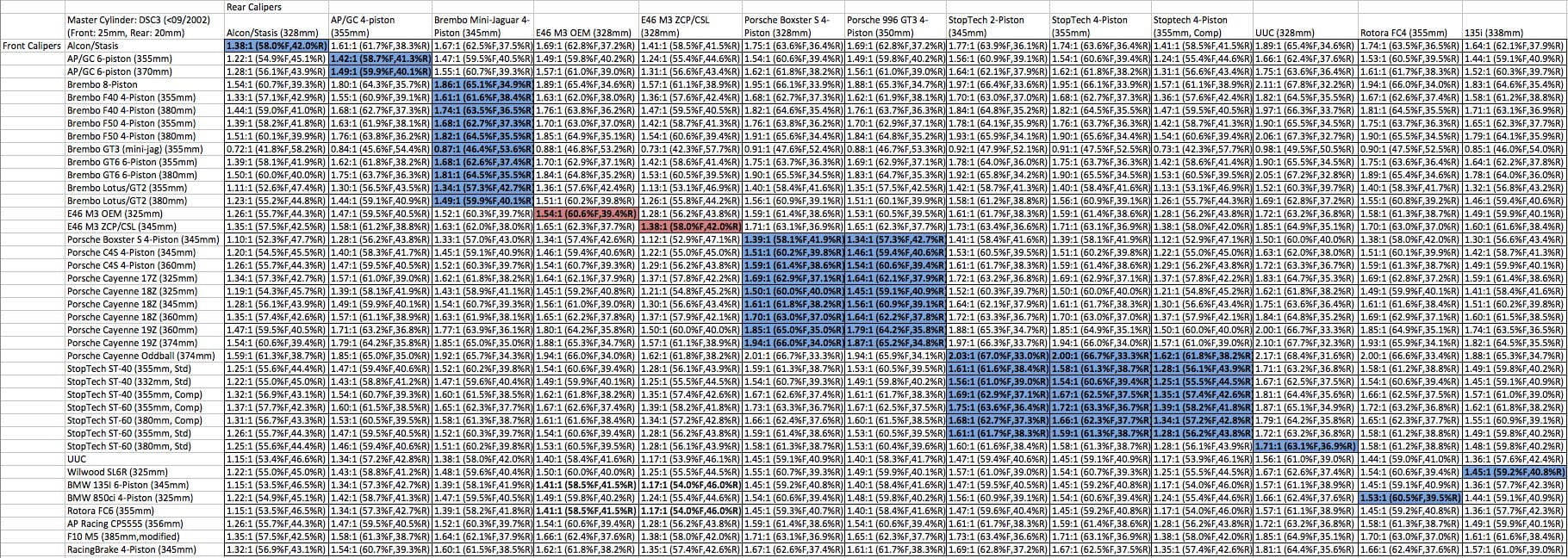

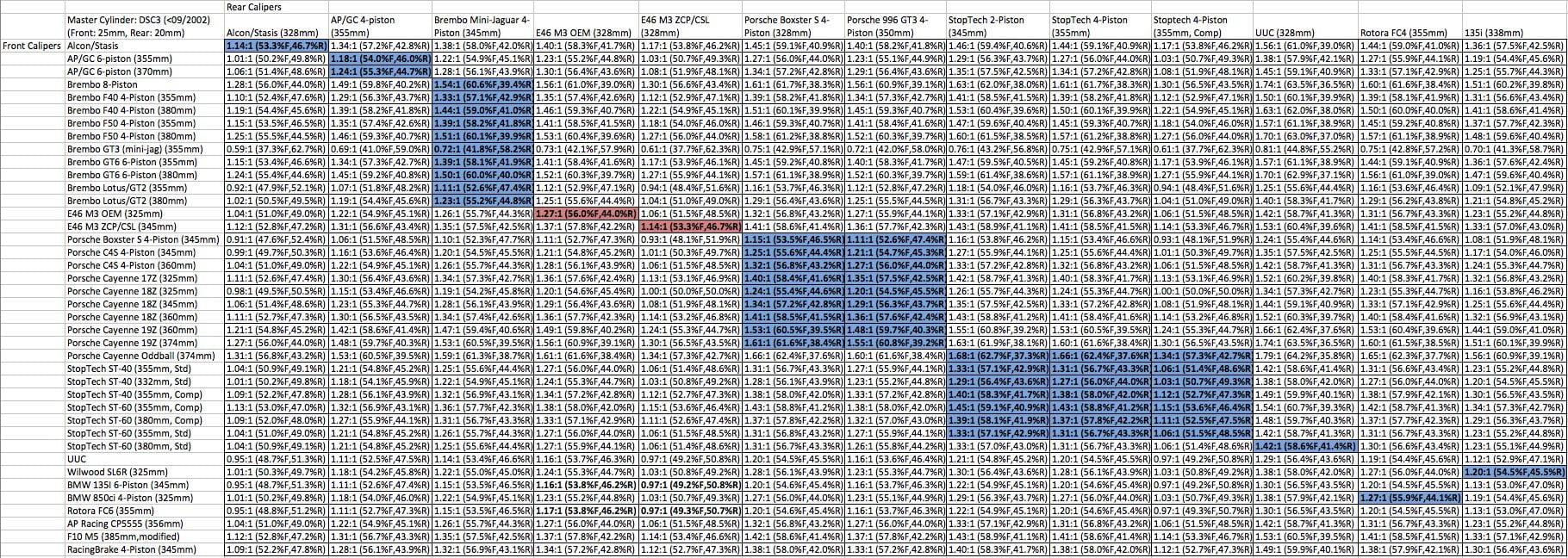

Update: Calculator with latest equations and data (Courtesy of CLAWHAMM3R on m3forum)

Brake Bias on E46 M3 with MK60-based Master Cylinder

(Front: 25mm, Rear: 22mm) (post-09/2002) (1:54.1 Stock Bias – 60.6%F 39.4%R)

Brake Bias on E46 M3 with DSC3-based Master Cylinder

(Front: 25mm, Rear: 20mm) (pre-09/2002) (1.27:1 Stock Brake Bias – 56.0%F 44.0%R)

Dimensions required: (default E46 M3 specifications listed in parentheses)

- Master cylinder piston(s) and Sizes (MK60-based vehicles, >09/2002: 25mm front, 22mm rear) (MK20-based vehicles, <09/2002: 25mm front, 20mm rear)

- Pedal ratio (3:1 mechanical lever)

- Coefficient of friction of pad material, front and rear (0.36)

- Brake pad width, front and rear (Front: 61mm; Rear: 54mm)

- Caliper types [fixed/floating] (floating)

- Number and sizes of all pistons in the brake caliper (Front: 1 piston, floating, 60mm; Rear Standard: 1 piston, floating, 42mm; Rear ZCP/CSL: 1 piston, floating, 46mm)

- Rotor diameter (Front Standard: 325mm; Front ZCP/CSL: 345mm; Rear: 328mm)

Constants:

- pi = 3.141592653589793238462643383279502884197169399375 10582097494459230781640628620899862803482534211706 79821480865132823066470938446095505822317253594081 28481117450284102701938521105559644622948954930381 96442881097566593344612847564823378678316527120190 91456485669…

Variables:

- Leg Force = 150 pounds

The first element necessary to get started is the individual line pressures generated for both the front and rear pistons within the master cylinder, obtained by Equation 1:

Equation 1: P = Fpedal / Apiston

- P = Pressure

- Fpedal = Force due to pedal operation

- Apiston = Area of master cylinder piston

The Force exerted by the pedal is obtained by Equation 2:

Equation 2: Fpedal = Fleg · Ratiopedal

- Fpedal = Force exerted by pedal operation

- Fleg = Force exerted on pedal from leg

- Ratiopedal = Distance from exertion of leg force to pivot point divided by distance from pivot point to master cylinder piston actuator

The Area of the master cylinder piston is obtained by Equation 3:

Equation 3: Apiston = pi · rpiston2

- Apiston = Area of master cylinder piston

- rpiston = radius of master cylinder piston

Equation 4 is used to determine the radius from a given diameter:

Equation 4: rpiston = Dpiston / 2

- rpiston = radius of master cylinder piston

- Dpiston = diameter of master cylinder piston

Brake torque generated at the wheel, individually Tf and Tr, is given by Equation 5:

Equation 5: T{f,r} = P · Atotal · Reffective · cF

- T{f,r} = Torque at wheel

- P = Pressure

- Atotal = Combined area of all pistons within a caliper

- Reffective = Effective radius of pad placement to rotor

- cF = Coefficient of friction of pad material

The total combined effective area of the caliper pistons is obtained by utilizing Equations 6, 7, 8 and 9 based on their respective caliper configurations (Floating: single-piston, Floating: 2-piston, Fixed: 4-piston, Fixed: 6-piston, Fixed: 8-piston):

For a Floating: single piston caliper:

Equation 6: Atotal = 2 · pi · rpiston2

- Atotal = Total combined effective area

- rpiston = radius of piston *

* – refer to Equation 4 to obtain radius from diameter)

For a Floating: 2-piston and Fixed: 4-piston caliper:

Equation 7: Atotal = 2 · pi · (rpiston_12 + rpiston_22)

- Atotal = Total combined effective area

- rpiston_1 = radius of piston 1 *

- rpiston_2 = radius of piston 2 *

* – refer to Equation 4 to obtain radius from diameter)

For a Fixed: 6-piston caliper:

Equation 8: Atotal = 2 · pi · (rpiston_12 + rpiston_22 + rpiston_32)

- Atotal = Total combined effective area

- rpiston_1 = radius of piston 1 *

- rpiston_2 = radius of piston 2 *

- rpiston_3 = radius of piston 3 *

* – refer to Equation 4 to obtain radius from diameter

For a Fixed: 8-piston caliper:

Equation 9: Atotal = 2 · pi · (rpiston_12 + rpiston_22 + rpiston_32 + rpiston_42)

- Atotal = Total combined effective area

- rpiston_1 = radius of piston 1 *

- rpiston_2 = radius of piston 2 *

- rpiston_3 = radius of piston 3 *

- rpiston_4 = radius of piston 4 *

* – refer to Equation 4 to obtain radius from diameter

The effective radius is calculated using Equation 10:

Equation 10: Reffective = rrotor – (wpad / 2)

- Reffective = effective radius of rotor

- rrotor = radius of rotor *

- wpad = width of brake pad **

* – refer to Equation 4 to obtain radius from diameter

** – width of brake pad is an estimate of the distance the center of the piston(s) from the rotor’s diameter and may not be the most precise way to gauge application of force (Noted by IntelOne)

Finally, Equation 11 gives the ratio of the front brake torque to that of the rear and is an index reflecting overall front:rear bias:

Equation 11: Bias = Tf / Tr

- Bias = index representing front to rear wheel brake torque ratio

- Tf = Brake torque generated at front wheel

- Tr = Brake torque generated at rear wheel

Equation 12 is used to convert from a ratio to a percent front:rear bias:

Equation 12:

% Biasfront = (Tf · 100%) / (Tf + Tr)

% Biasrear = (Tr · 100%) / (Tf + Tr)*

- % Biasfront = Bias percentage at front wheel

- % Biasrear = Bias percentage at rear wheel

- Tf = Torque generated at front wheel

- Tr = Torque generated at rear wheel

*alternately; one bias percentage can be calculated by subtracting the other from 100%

Courtesy of p0lar @ M3forum.net

23 Comments

Leave a ReplyCancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

How do you adjust break bias

Would you be able to add the AP Pro5000R 9660 with ZCP rears vs OE rear calipers for the MK60?

Hi, I have the Z4M Coupe (the 345mm fronts as std). Would the Renault Megane Brembo’s be a straight front swap when it comes to bias..

Maybe a stupid question but I can’t seem to figure it out myself.

Let’s say I have a stock M3 with MK20 system. Now I upgrade to the AP Racing caliper on the front and change nothing at the rear.

How is it possible, that the breake bias will switch to the rear? I get, that the piston size might be smaller even though there are 6 pistons. But the breaking power should be way higher of the AP calipers. Or am I missing something completely? Can’t imagine that the stock caliper would benefit more. Then were wouldnt be a point in switching for the bbk?

Hi , can you please add the m4 calipers front and rear on the mk60 pump thank you

Can you please add the M4 Calipers Fr and Rear on the DSC3 pump as well? I opened the spreadsheet but I cannot find anywhere to modify the Master Cylinder piston values. The cherry on top would be to supply all of the pad width, piston diams. etc. for the M3/M4 brakes =). Thanks!

Hey John,

I will submit that as a request!

What do the blue highlighted areas mean?

Hello, shouldn’t equation 3 be: A(f,r)=2•pi•r^2

Hello Guys, I just did the calculation twice to check to see if I’m doing it right (for stock e46 m3). I’m pretty confident I’m doing it right but I keep getting 49% for the front bias and I can’t seem to figure out where I’m off. The calculation is pretty straight forward. Do you mind checking to make sure the process is right?

The stock E46 M3 on MK40 DSC unit is 60/40 and the DSC3 is 56/44.

Very nice review. So what is best for the e46 m3

The best value is Aston Martin DB9 which is a newer find. We did an article on it: https://thebuildjournal.com/reviews/aston-martin-db9-bbk-retrofit-for-e46-m3-review

Hello.

That’s very interesting!

I’m building an S54 powered E46 Touring from a 325xi.

Any idea which setup would work best for that?

I don’t know how to find the stock bias for that vehicle given the different weight.

Thanks!

Happy New Year!

It seems to me that there is some sort of problem with the calculator. If I insert stock M3 brakes data it states:

Ratio (:1) 2.02

Front Bias 66.87%

Rear Bias 33.13%

Could you look into that? Otherwise it is very useful calculator, just right now I have some doubts trusting the results… 🙂

Hi, we do not maintain or create that calculator. That is something forum member has made through research and new data. It is pretty accurate from our estimations.

In your charts above I see that the OEM ratios are highlighted Red, but what are the Blue highlights? Are those the recommended ratios/combinations for different caliper brands/models? If so how are those determined?

It appears there are “recommended” ratios and biases both higher and lower than other “non-recommended” combinations. I apologize if I missed the explanation somewhere.

TIA

Awesomeness! But what is the desired bias ratio front to rear? Manfacturers typically put a lot of front bias to lock fronts first and keep the lawyers happy. I’m interested for track use. On older Porsche 911 the desired bias is 1.4 to 1.5 towards the front on stiff prepared cars. Thinking less for the e46 (non-M). Thoughts?

Hello . if I put some front 6p alcon calipers on a zcp 345 mm discs, which will be the bias. Thank you

Hi. You are a very clever man. Thsnks for the info. I have a 2005 m3 e46 non zcp/csl. I have just bought zcp caliper carriers with 345mm floating rotors. I have standard rear calipers. Will i have too much front brake bias to the front or is it minimal? I was thinking about buying zcp rear calipers. Thanks in advance.

You’re going to have about 2% more braking in the front or 2% less in rear, but you’re not going to feel any major setbacks with ZCP front and OEM rears.

Excellent thanks for your knowledge and replying so quickly.