N15 Design E46 M3 Electric Fan Mount DIY

The stock fan clutch cooling setup does a great job on our S54 engines, however sometimes it’s not enough. To add another layer to the situation, if your fan blades grenades inside your engine bay you can cause destruction to your hose, radiator, hood and other surrounding parts.

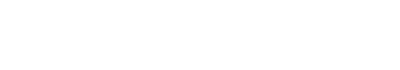

The N15 Design E46 M3 Electric Fan Mount is a great way to add a 16″ SPAL electric fan because it’s so easy to install. In addition, the AUX Fan Controller Mount (optional) allows you to retain the stock controller to run the fan on auto as an OEM style would. Don’t get intimidated of the crazy electric fan setups and the false “requirements” to run a fan controller. This one is truly easy to install.

Tools Required

- N15 Design E46 M3 Electric Fan Mount

- 16" SPAL fan or similar (SPAL 2024 16" Puller Fan 30102049 - $151.56)

- 4mm hex bit

- T25 torx bit

- 10mm socket

- 19mm socket

- 8mm wrench

- 32mm wrench

- Ratchet

- 3/16" drill bit

- Drill

- Wire stripper [amazon_link asins='B000OQ21CA' template='PriceLink' store='builjour-20' marketplace='US' link_id='ece54d1d-aff0-4bb8-8b56-740a4e811397']

- BMW Water Pump Pulley Locking Tool $25.95

- Coolant

- Funnel

❗ You don't need to remove the radiator for this job, however you'll need a special angle drill (or maybe even Dremel?) to make holes for the mount. I chose to take mine out only because I was already in the middle of another job.

2. Remove radiator fan shroud and fan.

2.2 Remove the 3 push pins holding the shield. There is one on top directly center, one driver and one passenger. Remove using pliers. I don’t have pictures of the passenger side of the shield because I don’t run that. This is a picture of the driver side shield.

❗ Be very careful when you remove the coolant expansion line from the upper radiator hose. It's a good idea to pull this so you don't damage the line when the radiator is moving around. This piece is very brittle!

8. Install fan using supplied hardware.

8.1 Plug in the fan using the stock connector.

8.2 Tuck wiring away from the belts and water pump. I zip tied mine to the back of the fan case.

8.3 Add coolant inside the system if you chose to drain your radiator in Step 3.

8.4 Bleed the cooling system properly. During this procedure the fan should turn on.

E46 M3 IAT Sensor Relocation DIY

The intake air temperature (IAT) sensor is integrated into the E46 M3 stock MAF location inside the intake tube and although the OEM location works, it is prone to heat soak which will allow the ECU to pull timing resulting in power loss. We made this IAT relocation kit so we can move the sensor location to a location outside the MAF that is optimized for air flow thus the engine is less likely to pull timing due to false temperature readings.

The install is fairly simple, but you will need to solder two wires together. There are some vendors that sell a plug and play harness so if you don’t want to cut and solder your stock MAF wires you can purchase their kit.

Tools Required

- Soldering kit (including soldering wire) [amazon_link asins='B06XZ31W3M' template='PriceLink' store='builjour-20' marketplace='US' link_id='74082f78-8dd9-40e1-9903-ca49edc52f5d']

- Shrink tube [amazon_link asins='B075WR9FVL' template='PriceLink' store='builjour-20' marketplace='US' link_id='3f69cf49-a1b5-4d36-b69c-d4ab4bcfee01']

- Wire cutter [amazon_link asins='B000OQ21CA' template='PriceLink' store='builjour-20' marketplace='US' link_id='309825f7-3e61-4369-854d-60fba522382a']

- Razor blade [amazon_link asins='B0006O5JR4' template='PriceLink' store='builjour-20' marketplace='US' link_id='14117261-e1ce-451e-bb96-50ddc8c5c444']

- Lighter

- Electric tape

- Scissors

- IAT relocation sensor kit

-

Install Directions

1. Remove MAF and locate the wires numbered 1-5. Remove rubber grommet.

2. Cut and remove some of the plastic wiring loom with scissors then cut Wire #1 about 2″ down from the plug.

❗ Doesn't have to be cut 2" down from the plug side. I only recommend 2" so you have enough wire to work with in case you want to remove IAT in the future.

9. Your wires are ready for soldering. Solder both wires.

How to Solder: Watch Video

Okay so now that we have the IAT sensor wired up, we need to install the IAT sensor somewhere. I’m leaving this step open ended because the IAT installation depends on which intake you’re running.

Personally for me I’m running the Eventuri intake so I decided to drill a hole in the intake bracket right below the filter. This works perfect because my PSDesigns Headlight Duct kit allows air right into the filter and IAT sensor.

I assume most of you are running the stock box. The IAT sensor can be installed on the lower half of the intake box right above the drain outlet. All you need is a 7/16″ drill bit to create a hole in the box. M3support.net user “s54smg2” did an excellent write up for the IAT relocation on S54 intake.

Remove Your Bumper in Seconds, Pop Latch Quick Release for Front Bumper DIY

Instantly remove your front bumper cover in seconds! We’ve released a custom mounting solution for the Pop Latch Quick Release and we’re going to show you how to do the install. The studs use the factory hex stud location on Kevlar bumper supports for an easy bolt-on installation. Oh also, we now offer custom paint matched latches as an add-on option!

4. Remove thread insert and install new stud from Pop Latch kit

The Kevlar bumper has a hollow inside and you can get to the opening through the immediate sides of the support beam. Once the stud is inserted, you must back the stud towards the back and lock it down with the supplied washer/nut. The back of the stud should be almost touching the backside of the hollow bumper beam.

Aerodynamics

-

-

Trackspec Hood Vent Kit - E46 M3

$359.99 – $367.99Price range: $359.99 through $367.99-

-

-

Trackspec Hood Vent Kit - E85 Z4 M

$359.99 – $367.99Price range: $359.99 through $367.99-

Trackspec Hood Vent Kit (Center) - E90 E92 M3

$229.99 – $235.99Price range: $229.99 through $235.99-

-

Trackspec Hood Vent Kit (Sides) - E85 Z4 M

$359.99 – $367.99Price range: $359.99 through $367.99-

-

Adjustable Splitter Cable Rods

$70.00 – $95.00Price range: $70.00 through $95.00-

Jack Pads - E36

$13.20-

Trackspec Hood Vent Kit (Center) - E36 M3

$229.99 – $237.99Price range: $229.99 through $237.99

Trackspec E46 M3 Hood Vent Kit Install DIY

Yes you’re going to cut your hood, but don’t be intimidated – it’s not too hard. A properly designed hood vent kit like the Trackspec E46 M3 Hood Vent Kit allows for two major things: heat dissipation for engine cooling and pressure release for improved aerodynamics. A third possibly? It looks bad ass!

There are three different “kits” for the Trackspec hood vents. One is the entire kit and the other two are just sectional pieces. We are now a re-seller for Trackspec so you can purchase the E46 M3 kits here. They sell the 3-piece kit as well as the center only and side only kits.

-

Trackspec Hood Vent Kit - E46 M3

$359.99 – $367.99Price range: $359.99 through $367.99-

Trackspec Hood Vent Kit (Center) - E46 M3

$219.99 – $227.99Price range: $219.99 through $227.99-

Trackspec Hood Vent Kit (Sides) - E46 M3

$229.99 – $237.99Price range: $229.99 through $237.99Required Tools

- Angle grinder

- Dremel Rotary + Reinforced Cut Off Wheel [amazon_link asins='B0006O8RZA' template='PriceLink' store='builjour-20' marketplace='US' link_id='e6ecf1b1-f512-4b4d-a4cd-94ea52c65ea3']

- 100-grit sandpaper or similar or file

- Anti-rust coating paint

- Rivet tool [amazon_link asins='B000NPT74C' template='PriceLink' store='builjour-20' marketplace='US' link_id='58b422a1-e313-4c9e-b119-41b7de13bb8c']

- Work stand [amazon_link asins='B000LQN5GO' template='PriceLink' store='builjour-20' marketplace='US' link_id='67fabdb1-f932-46e9-9816-48a1c9401393']

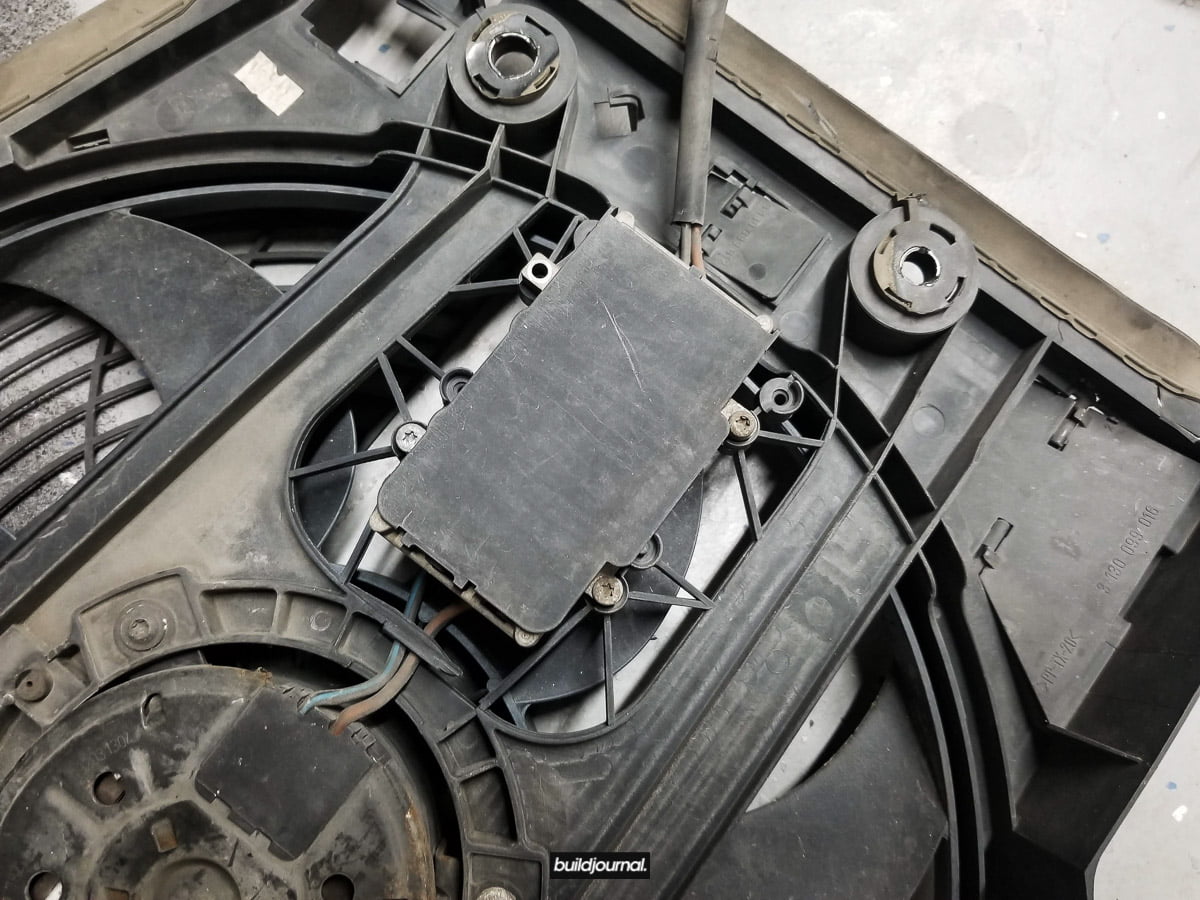

- String or yarn to measure

- Torx bits

- Ratchet

- Painter's tape

- Safety goggles

Install Directions

1. Remove hood

Pop open your hood and remove the washer grommet to pull the washer lines and all necessary lines. There will be 2 torx screws on both hinges. You can completely remove the bottom two on each side, but just loosen the top ones since you can slide out the hood. Before you loosen the torx bolts, make sure you mark the bolts so you can re-align it later. Have a second set of hands to catch and remove the hood once loosened.

Both driver and passenger sides of the hood have reinforced structure underneath the hood which you will need to cut through. You’re going to have to cut through a good amount of aluminum framing, but I can confirm it doesn’t sacrifice the structural integrity of the hood even with all that cutting.

First Time Out With The RS Future Wing at Buttonwillow CW13

First of all a huge thank you to Amir (@that911) for making me this RS Future wing just in time for my track day slash shakedown day before Bimmer Challenge Round 5 at Auto Club Speedway. I always like to say, I’m all about function, but if it doesn’t look good, I don’t fuck with it. I’m glad this wing puts a checkbox in both criterias.

I started the 1st session with some hardware failure so I was forced to retire after the outlap. On the second session, I immediately noticed the car’s imbalanced handling characteristics so I immediately called Amir for some track side support and he was prompt to pick up and discuss some suspension tuning options even though he was out instructing at the track himself. My current spring rates are not ideal for aero and I have a really stiff rear spring to begin with. The wing didn’t help.

On the high speed turns my car would not turn in. It almost felt like I had a broken steering rack. Turns out the front was way too soft so I bumped up the front rebound and softened the rears a bit. The next session I went back out and immediately it felt better, but still lazy. It wasn’t until the fifth and last session, also probably the hottest part of the day, when I felt pretty comfortable with the setup and I started going for time. With my Nexen SUR4 (non-G) tires I managed to clock a 1:58.16 which was a new personal best, however not by much. I’m pretty sure if I ran in the morning sessions I would’ve been a second or two faster.

I plan to make a few more changes to the setup. I’m even thinking about downgrading to the MCS 1WNR setup with stickier tires. Car definitely has potential to be in the 55’s.

E46 M3 Fuel Injector DIY

The stock E46 M3 S54 Bosch fuel injector static flow rate is rated at 260 cubic centimeters (cc) per minute at 43 PSI. The purpose of taking out my injectors were to clean it since a buddy of mine had a flow rate of 150 cc on his injectors after 150K+ miles of usage. Little did I know my injectors were going to be worse! If your car is in the 100K range, I would consider cleaning the injectors. Scroll down through the article to see what that process was like for me, but first we’ll need to take out the injectors. So here is a little DIY for removing and installing injectors.

Difficulty

4/10

Time

4 hr

Cost

$150

Vehicle symptoms for dirty or clogged injectors

If you’re dealing with any of the following symptoms, as stated from injectorrx.com, you most likely have dirty, clogged or leaky injectors.

- Starting issues

- Poor idle

- Failed emissions

- Poor Performance

- Engine does not reach full RPM

- Increased fuel consumption

- Rough engine performance

- Surging and bucking under various throttle loads

- Smoke from the tail pipe

- Engine Knock or Detonation which can lead to catastrophic engine failure

- Pollution

The solution

Get your injectors cleaned! There are several injector cleaning companies you can find. I chose to go to RC Fuel Injection in Torrance, CA since they’re relatively local to my area. They clean, balance and calibrate your injectors to new-like state including new o-rings. They completed my cleaning in less than 24 hours and I was able to pickup the very next day after I dropped off. They also include a test sheet to show the old and new flow rate. Scroll below to see the print out for my injectors. You’d be surprised.

Instructions to remove your injectors for cleaning

Disconnect the negative (-) battery terminal from your car after you drain the fuel!

1. Remove cabin filter and strut bar

1.1 Remove 4 nuts holding front strut bar.

1.2 Remove 4 torx screws holding cabin filter housing, remove filter.

1.3 Remove strut bar.

2. Drain fuel from lines

2.1 Unplug Fuse #54 from glove box. It should be a yellow 20A fuse.

2.2 Start car up and let engine stall. This will remove most of the fuel in your lines.

2.3 Reinstall the fuel pump fuse back in. Don’t start the car again or else you need to re-do this process over again.

3. Remove Air & Fuel Rail

3.1 Disconnect plenum-side breather valve via squeeze clip.

3.2 Disconnect breather valve on air rail.

3.3 Remove the 2 silver 10mm hex bolts on the air rail. First one is by the TPS sensor above cylinder 1. The second bolt is in the rear between cylinder 5 and 6. I had to use a swivel head to get to it.

3.4 Disconnect the vacuum tube at the very ar end of the air rail. Be very careful not to drop it down the engine bay as I did!

3.5 This step is going to be different for most of you. I have an E85 kit, so my plastic fuel injector harness cover piece was already detached. For those that are stock, you’ll need to unclip the plastic tabs remove. Don’t completely remove the cover, but just unclip it so the air and fuel rail can come out.

3.6 Use a pry bar against the the engine head to lift the air rail up. Start at the side closest to the front of the car. The air rail is connected via 6 plastic air valves that are pressure fitted via o-rings. Once you pry the first few ones apart, you can lift the remaining.

3.7 Remove all 6 air valves by twisting them out. Some will be stuck on the air rail and some on the throttle body. You should clean these before they go back on.

3.8 Now to the fuel rail. There are a total of 6 metal tabs holding in the injectors to the rail and one metal tab holding in the fuel feed line which is located between cylinder 5 and 6 in the rear. Use a flat head to pry the clips apart.

3.9 Pry the fuel rail as you did for the air rail. Injectors will pop out one by one.

3.10 Careful not to pull out the rail all the way just yet. You must disconnect each injector wiring harness.

4. Remove injectors

4.1 Eventually they will all pop out like this attached to the rail. To remove the injectors from the rail, just simply twist them off. They are pressure fitted via o-rings. Take note of the orientation of the injector plugs for re-installation.

6. Installing injectors

Installing is the trickiest part of this DIY because since the injectors and air valves are pressure fitted with o-rings, it’s really hard to get those back in by pushing down.

6.1 Twist injectors into fuel rail and insert the metal clips you removed in step 3.8. Make sure the clips are seated properly as pictured below.

6.2 Apply some engine oil or silicone grease, in very small amounts, to the o-rings on the air valves to lubricate when installing the air rail back on. Twist in air valves onto throttle body.

6.3 Apply some engine oil or silicon grease to the injector o-rings as well. Dry pressure installation may damage your o-rings. Take the entire fuel rail assembly and install the injectors back in. Watch the injector nozzle alignment as you install. You’re going to need to wiggle each injector to make them slot right in. The 2 threaded metal tabs on the fuel rail will go behind the throttle body mount. Also keep an eye on the fuel feed line alignment between cylinders 5 and 6.

6.4 Once the injectors are in the hole, you’re going to need a good amount of top pressure to fit them in. In my case even with some lubricant, it was very difficult to get them in. I do not advise this method, but I had to get a small mallet to tap the fuel rail to push each injector in. One thing you should make sure to do is make the fuel rail go down evenly. Don’t push in one side completely and expect the other end to line up. Once properly seated, the fuel rail metal tab holes will line up with the throttle body.

6.5 Insert the metal clip for the fuel feed line.

6.6 Install the air rail back in. Same method as fuel rail.

6.7 Install the two 10mm bolts.

6.8 Install the rear vacuum hose back in. Turn the key to the 2nd position (which primes fuel into the lines) and check for fuel leaks.

6.9 If there are no fuel leaks, reverse install from the directions earlier to get everything back together. You’re done!

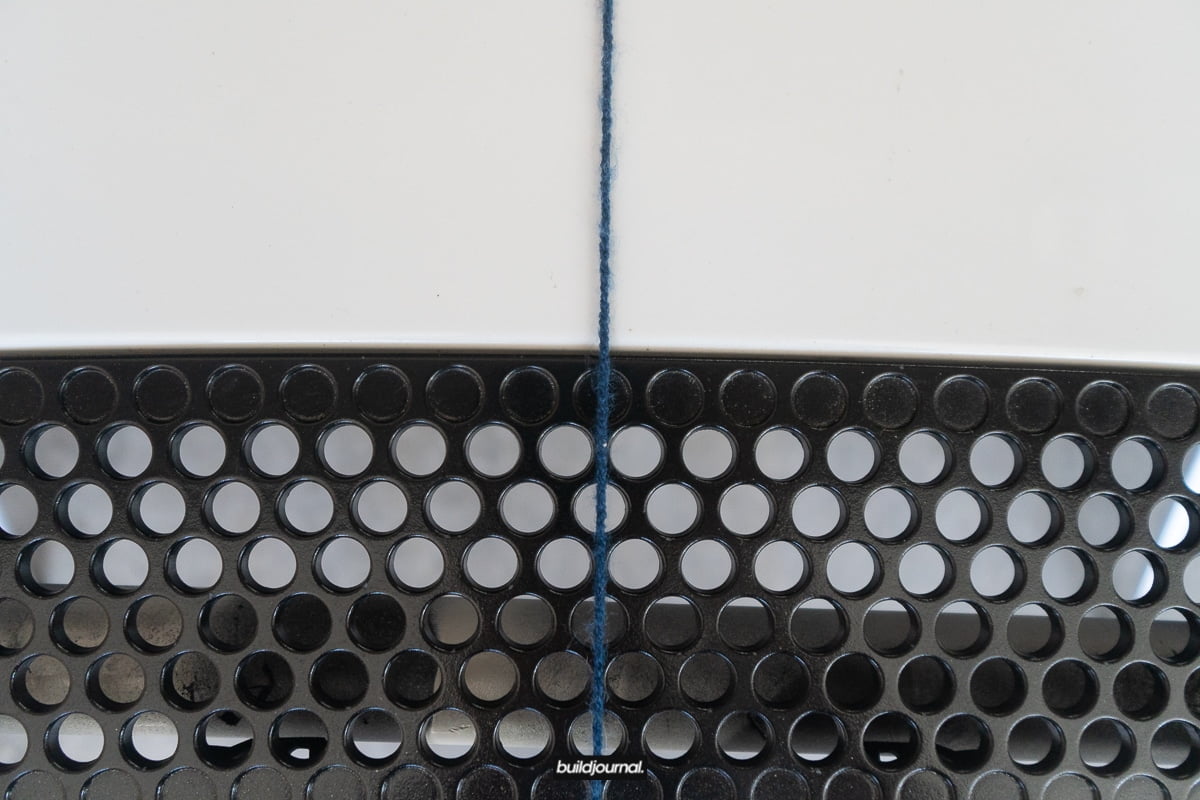

Ultimate BMW E46 M3 Torque Spec Guide

Use this guide as a cheat sheet for all the torque values for your E46 M3. If you’re like me, I even forget what the basic oil drain plug and filter housing torque specs are. From door panel specs to engine head torque values we have it all listed for you. Don’t over tighten another bolt ever again!

If you want a physical copy for the garage we formatted a printable copy available for download below. Our chart torque specs were compiled from BMW E46 3 Series (1999-2005) Service Manual by Bentley Publications.

Download Our Guide

We made a printer-friendly version for your garage. No more dirty phones.

[mc4wp_form id=”3965″]

Need a new torque wrench?

Schwaben Digital Torque Wrenches

| Category | Location | Bolt | Ft-lb | Nm | In-lb |

|---|---|---|---|---|---|

| Brakes | Bleeder screws | 7mm | 3.7 | 5 | |

| Brakes | Bleeder screws | 11mm | 12 | 16 | |

| Brakes | Caliper to brake pad carrier mounting bolts | 22 | 30 | ||

| Brakes | Brake rotor to hub mounting screw | 12 | 16 | ||

| Brakes | Front caliper to front steering arm | 81 | 110 | ||

| Brakes | Rear caliper to rear trailing arm | 48 | 65 | ||

| Brakes | Brake master cylinder to brake booster | 19 | 26 | ||

| Brakes | Brake fluid lines to master cylinder | 13 | 18 | ||

| Brakes | Brake booster to bulkhead | 16 | 22 | ||

| Brakes | Brake fluid line to master cylinder or hydraulic unit | 13 | 18 | ||

| Brakes | ABS wheel speed sensor to steering arm / trailing arm | 6 | 8 | ||

| Brakes | Rotational rate sensor to bracket | 6 | 8 | ||

| Brakes | Sensor bracket to body | 6 | 8 | ||

| Brakes | Pressure sensor to hydraulic unit | 14 | 19 | ||

| Brakes | Pressure sensor to master cylinder | 11 + 3 | 15 + 4 | ||

| Brakes | Brake caliper to steering arm | 81 | 110 | ||

| Engine | Engine oil drain plug | M12 | 18 | 25 | |

| Engine | Oil filter cover filter housing | 18 | 25 | ||

| Engine | Oxygen sensor to exhaust manifold | 37 | 50 | ||

| Engine | Spark plug to cylinder head | 18 | 25 | ||

| Engine | Intake manifold to cylinder head | M7 | 11 | 15 | |

| Engine | Intake manifold to cylinder head | M8 | 16 | 22 | |

| Engine | Coolant drain plug to cylinder block | 18 | 25 | ||

| Engine | Engine mount to subframe | M10 | 33 | 45 | |

| Engine | Engine mount to subframe | M7 | 15 | 20 | |

| Engine | Engine mount to subframe | M8 | 15 | 20 | |

| Engine | Radiator drain screw to radiator | 2.5 | 22 | ||

| Engine | Cylinder head to engine block (stage 1) | Torx E12 M10 | 40 | 55 | |

| Engine | Cylinder head to engine block (stage 2) | Torx E12 M10 | +90° | +90° | |

| Engine | Cylinder head to engine block (stage 3) | Torx E12 M10 | +90° | +90° | |

| Engine | Secondary chain guide to cylinder head | 10 | 98 | ||

| Engine | Camshaft bearing cap to cylinder head | M7 | 10 | 14 | |

| Engine | Impulse wheel studs to intake camshaft | M7 | 15 | 20 | |

| Engine | Exhaust camshaft locating stud | 15 | 20 | ||

| Engine | Primary chain tensioner preload | 0.7 | 6 | ||

| Engine | Sprocket assembly to camshaft (initial torque) | 5 | 44 | ||

| Engine | Sprocket assembly wheel to camshaft | M7 Torx | 15 | 20 | |

| Engine | Sprocket assembly wheel to camshaft | M6 | 8 | 10 | |

| Engine | VANOS unit to cylinder head | M6 | 10 | 89 | |

| Engine | VANOS unit to cylinder head | M7 | 10 | 14 | |

| Engine | Sealing plug to VANOS unit | 37 | 50 | ||

| Engine | Oil line to VANOS unit (banjo bolt) | 24 | 32 | ||

| Engine | Primary chain tensioner cylinder to cylinder head | 52 | 70 | ||

| Engine | Cylinder head cover to cylinder head | M6 | 10 | 89 | |

| Engine | Exhaust manifold to cylinder head | M7 | 15 | 20 | |

| Engine | Mounting bracket to cylinder block | M10 | 33 | 47 | |

| Engine | Mounting bracket to intake manifold | M6 | 7 | 10 | |

| Engine | Vibration damper | 302 | 410 | ||

| Engine | Hub to crankshaft | ||||

| Engine | Vibration damper to crankshaft hub | M8 | 16 | 22 | |

| Engine | Lower timing cover to cylinder block | M6 | 10 | 89 | |

| Engine | Oil pan to engine block (8.8 grade) | M6 | 10 | 89 | |

| Engine | Oil pan to engine block (10.9 grade) | 9 | 12 | ||

| Engine | Sprocket assembly to camshaft | M7 Torx | 15 | 20 | |

| Engine | Sprocket assembly to camshaft | M6 | 10 | 89 | |

| Engine | Cylinder head cover to cylinder head | 10 | 89 | ||

| Engine | Hydraulic piston to splined shaft | M6 | 10 | 89 | |

| Engine | Oil pressure switch to oil filter housing | 20 | 27 | ||

| Engine | Oil drain plug to oil pan | M12 | 18 | 25 | |

| Engine | Oil pan to engine block (10.9 grade) | M6 | 12 | 106 | |

| Engine | Transmission bellhousing to oil pan | M8 Allen | 17 | 24 | |

| Engine | Transmission bellhousing to oil pan | M8 Torx | 15 | 21 | |

| Engine | Oil pump to engine block | M8 | 16 | 22 | |

| Engine | Oil pump sprocket to oil pump shaft (left-hand threads) | M10 | 18 | 25 | |

| Engine | Intake camshaft sensor to cylinder head | 3.5 | 5 | ||

| Engine | VANOS solenoid to VANOS control unit | 22 | 30 | ||

| Engine | Knock sensor to cylinder block | 15 | 20 | ||

| Engine | ECT sensor to cylinder head | 10 | 13 | ||

| Engine | Engine block drain plug to block | 18 | 25 | ||

| Engine | Radiator drain plug to radiator | 3 | 27 | ||

| Engine | Radiator bleed screw | 2.5 | 22 | ||

| Engine | Fan clutch nut to coolant pump (left-hand threads; without BMW tool) | 29 | 40 | ||

| Engine | Fan clutch nut to coolant pump (left-hand threads; with BMW tool) | 22 | 30 | ||

| Engine | Fan to viscous clutch | 10 | 89 | ||

| Engine | Coolant pump to timing chain cover | 10 | 89 | ||

| Engine | Coolant pump pulley to coolant pump | 10 | 89 | ||

| Exterior | Door hinge to door | 15 | 20 | ||

| Exterior | Door check to door | 16 | 24 | ||

| Exterior | Tailgate to tailgate hinge | M8 | 15 | 20 | |

| Exterior | Hatchback window to hinge | M8 | 12 | 16 | |

| Exterior | Lock nut for stop buffer | M8 | 11 | 15 | |

| Exterior | Outside mirror to door | M6 | 4.5 | 6 | |

| Exterior | Bumper to impact absorber | M10 | 39 | 41 | |

| Exterior | Bumper bracket to impact absorber | M10 | 30 | 41 | |

| Exterior | Impact absorber to chassis | M8 | 16 | 22 | |

| Exterior | Front bumper to bumper bracket | M8 | 16 | 22 | |

| Exterior | Front bumper bracket to impact absorber | M10 | 41 | 55 | |

| Exterior | Rear bumper bracket to impact absorber | M10 | 31 | 42 | |

| Exterior | Window regulator guide rail to door | 9 | 80 | ||

| Exterior | Side-impact airbag to door | 8.5 | 75 | ||

| Exterior | Window to regulator guide | 8 | 71 | ||

| Exterior | Window to guide | 8 | 71 | ||

| Exterior | Vent window to body | M6 | 6.2 | 55 | |

| Exterior | Window regulator to door | 7 | 9 | ||

| Exterior | Window motor to regulator | 4 | 5 | ||

| Exterior | Door lock adjustment screw | 3 + 2 | 27 + 18 | ||

| Exterior | Outside handle to lock (left-hand thread) | 2.0 ± 0.4 | 18 ± 3.5 | ||

| Exterior | Striker plate to body pillar | 18 | 24 | ||

| Exterior | Sunroof panel to roof | 4.5 | 40 | ||

| Exterior | Wind blocker to roof | 1 | 9 | ||

| Exterior | Sunroof motor to sunroof carrier | 2.8 | 25 | ||

| Exterior | Filler plug to hydraulic unit | 10 + 1 | 89 + 9 | ||

| Exterior | Hydraulic unit to body | 10 | 89 | ||

| Exterior | Front wiper arm to wiper shaft | 22 | 30 | ||

| Exterior | Rear wiper arm to wiper shaft | 7 | 9.5 | ||

| Exterior | Center wiper assembly mount to cowl | 10 | 88 | ||

| Exterior | Wiper arm to wiper shaft | 22 | 30 | ||

| Exterior | Wiper shaft nut at cow | 10 | 88 | ||

| Exterior | Wiper motor to rear deck | 7 | 9.5 | ||

| Exterior | Rear window button to rear window | 7 | 9.5 | ||

| Exterior | Wiper shaft housing to rear window | 7 | 9.5 | ||

| Exterior | Rear spoiler to rear glass | 4 | 6 | ||

| Exterior | Coolant hose clamp (32-48mm) | 2.5 | 22 | ||

| Exterior | Steering column to dashboard reinforcement | 16 | 22 | ||

| Exterior | A/C line to A/C compressor | 15 | 20 | ||

| Interior | Airbag to door | 8.5 | 75 | ||

| Interior | Door lock to door | M6 | 9 | 80 | |

| Interior | Front seat to floor | 33 | 45 | ||

| Interior | Seat belt end to seat | 35 | 48 | ||

| Interior | Steering wheel to steering column spindle shaft | 46 | 63 | ||

| Interior | Front seat to floor | M10 | 33 | 45 | |

| Interior | Tensioner mounting bracket to seat rail | 18 | 24 | ||

| Interior | Tensioner to mounting bracket | 35 | 48 | ||

| Interior | Seat belt anchor bar to door sill | 23 | 31 | ||

| Interior | Seat belt to B-pillar sliding anchor | 23 | 31 | ||

| Interior | Seat belt reel to B-pillar bottom | 23 | 31 | ||

| Interior | Sliding seat height adjuster to B-pillar | 18 | 24 | ||

| Interior | Airbag to steering wheel (MFL) | 8 | 71 | ||

| Interior | Airbag cover strap to dashboard | M6 | 7 | 9 | |

| Interior | Passenger air bag to dashboard | M8 | 16 | 22 | |

| Interior | Side-impact airbag to door | 8.5 | 75 | ||

| Interior | HPS airbag to body | 8 | 11 | ||

| Interior | HPS airbag mounting bracket to A or B-pillar | 2.5 | 22 | ||

| Interior | HPS gas generator to dashboard reinforcement | M6 | 4 | 35 | |

| Suspension | Front differential filler plug to housing | 48 | 65 | ||

| Suspension | Rear differential filler plug to housing | 52 | 70 | ||

| Suspension | Control arm ball joint to suspension subframe | 66 | 90 | ||

| Suspension | Front subframe to frame rails (8.8 grade) | M12 | 57 | 77 | |

| Suspension | Front subframe to frame rails (10.9 grade) | M12 | 81 | 110 | |

| Suspension | Front subframe to frame rails (12.9 grade) | M12 | 77 | 105 | |

| Suspension | Front end reinforcement to frame rails or suspension subframe (initial torque) | M10 | 44 | 59 | |

| Suspension | Front end reinforcement to frame rails or suspension subframe | M10 | 90° + 30° | 90° + 30° | |

| Suspension | Stabilizer bar to frame rail | M8 | 16 | 22 | |

| Suspension | Steering column universal joint clamping screw | M8 | 16 | 22 | |

| Suspension | Control arm mounting bracket to subframe | M10 | 44 | 59 | |

| Suspension | Control arm ball joint bracket to subframe | M12 | 57 | 77 | |

| Suspension | Engine mount to subframe | M10 | 33 | 45 | |

| Suspension | Front end reinforcement to chassis and subframe (tubular style) | M10 | 31 | 42 | |

| Suspension | Front end reinforcement to chassis and subframe (pan style; stage 1) | M10 | 44 | 59 | |

| Suspension | Front end reinforcement to chassis and subframe (pan style; stage 2) | M10 | + 90° | + 90° | |

| Suspension | Road wheel to hub | 74 ± 7 | 100 ± 10 | ||

| Suspension | Stabilizer bar link to strut | 44 | 59 | ||

| Suspension | Steering tie rod to steering arm | 48 | 65 | ||

| Suspension | Steering arm to control arm | 48 | 65 | ||

| Suspension | Steering arm pinch bolt at strut housing | 60 | 81 | ||

| Suspension | Front strut assembly to strut tower (selflocking nuts) | 18 | 24 | ||

| Suspension | Front upper strut mount to strut tower (18mm flange) | M8 | 18 | 24 | |

| Suspension | Front upper strut mount to strut tower (21mm flange) | M8 | 25 | 34 | |

| Suspension | Front upper strut mount to strut shaft | M14 | 47 | 64 | |

| Suspension | Front end reinforcement to front subframe or body frame rails (stage 1) | M10 | 43 | 59 | |

| Suspension | Front end reinforcement to front subframe or body frame rails (stage 2) | M10 | 90° + 30° | 90° + 30° | |

| Suspension | Control arm ball joint to subframe | M14 | 66 | 90 | |

| Suspension | Control arm bushing carrier to body | M10 | 43 | 59 | |

| Suspension | Steering rack to subframe | M10 | 31 | 42 | |

| Suspension | Subframe to body (8.8 grade) | M12 | 57 | 77 | |

| Suspension | Subframe to body (10.9 grade) | M12 | 81 | 110 | |

| Suspension | Subframe to body (12.9 grade) | M12 | 77 | 105 | |

| Suspension | Control arm rear bracket to subframe | M10 | 44 | 59 | |

| Suspension | Inner ball joint to control arm | M14 | 59 | 80 | |

| Suspension | Inner ball joint mount to subframe | M12 | 57 | 77 | |

| Suspension | Stabilizer anchor to subframe | M8 | 16 | 22 | |

| Suspension | Subframe adapter to body | M10 | 44 | 59 | |

| Suspension | Subframe front to body (8.8 grade) | M12 | 57 | 77 | |

| Suspension | Subframe front to body (10.9 grade) | M12 | 81 | 110 | |

| Suspension | Subframe front to body (12.9 grade) | M12 | 77 | 105 | |

| Suspension | Outer ball joint to steering arm | M12 | 48 | 65 | |

| Suspension | Control arm rear | 44 | 59 | ||

| Suspension | Stabilizer bar bushing brackets to subframe | 16 | 22 | ||

| Suspension | Stabilizer bar link to stabilizer bar | M10 | 48 | 65 | |

| Suspension | Stabilizer bar link to strut | M10 | 48 | 65 | |

| Suspension | Brake rotor to wheel hub | 12 | 16 | ||

| Suspension | Collar nut to stub axle | 214 | 290 | ||

| Suspension | ABS pulse sensor to steering arm | 8 | 71 | ||

| Suspension | Tie rod to steering arm | 48 | 65 | ||

| Suspension | Drive flange collar nut to front hub | 310 | 420 | ||

| Suspension | Control arm bracket to front axle subframe | 44 | 59 | ||

| Suspension | Front axle differential drain / fill plug | 48 | 65 | ||

| Suspension | Control arm bracket to front suspension subframe | 44 | 59 | ||

| Suspension | Hydraulic hoses to power steering pump | M14 Banjo | 26 | 35 | |

| Suspension | Hydraulic hoses to power steering pump | M16 Banjo | 30 | 40 | |

| Suspension | Steering arm to lower ball joint | 48 | 65 | ||

| Suspension | Steering column to steering rack | 16 | 22 | ||

| Suspension | Steering arm clamping bolt at strut housing | 60 | 81 | ||

| Suspension | Subframe rear to adapter | M12 | 81 | 110 | |

| Suspension | Bearing pedestal to oil pan | 33 | 45 | ||

| Suspension | Input flange collar nut to differentia | Align | Align | ||

| Suspension | Airbag to steering wheel | 8 | 71 | ||

| Suspension | Pinch bolts at steering columns joints | 16 | 22 | ||

| Suspension | Universal joint pinch bolt at steering column | 16 | 22 | ||

| Suspension | Steering column to dashboard carrier | 16 | 22 | ||

| Suspension | Outer tie rod end to steering arm replace self-locking nut | 48 | 65 | ||

| Suspension | Outer tie rod end lock nut | 33 | 45 | ||

| Suspension | Steering column flexible joint to steering rack shaft | 16 | 22 | ||

| Suspension | Steering fluid lines | M14 Banjo | 26 | 35 | |

| Suspension | Steering fluid lines | M16 Banjo | 30 | 40 | |

| Suspension | Inner tie rod to steering rack | 74 + 7 | 100 + 10 | ||

| Suspension | Tie rod lock nut | 33 | 45 | ||

| Suspension | Rear lower control arm to rear trailing arm | 57 | 77 | ||

| Suspension | Rear trailing arm bracket to body | 57 | 77 | ||

| Suspension | Rear shock absorber to trailing arm (car in normal loaded position) | 74 | 100 | ||

| Suspension | Rear shock absorber upper mount to body | M8 | 21 | 28 | |

| Suspension | Drive axle to final drive flange (20mm bolt) | M10 | 61 | 83 | |

| Suspension | Drive axle to final drive flange (46mm bolt) | M10 | 74 | 100 | |

| Suspension | Drive axle to final drive flange (46mm bolt; silver) | M10 | 59 | 80 | |

| Suspension | Trailing arm to front bracket | 81 | 110 | ||

| Suspension | Drive axle collar nut to drive flange | M24 | 184 | 250 | |

| Suspension | Drive axle collar nut to drive flange | M27 | 221 | 300 | |

| Suspension | Upper control arm to rear subframe | M12 | 57 | 77 | |

| Suspension | Upper control arm to trailing arm | M12 | 81 | 110 | |

| Suspension | Lower control arm to rear subframe | M12 | 81 | 110 | |

| Suspension | Lower control arm to trailing arm | M12 | 81 | 110 | |

| Suspension | Differential to subframe front bolt | M12 | 81 | 110 | |

| Suspension | Differential to subframe rear bolt | M14 | 128 | 174 | |

| Suspension | Driveshaft to differential flange | M10 Compressed | 47 | 64 | |

| Suspension | Driveshaft to differential flange | M10 Torx | 63 | 85 | |

| Suspension | Lower control arm to subframe | M12 | 81 | 110 | |

| Suspension | Subframe to body | M12 | 57 | 77 | |

| Suspension | Upper control arm to subframe | M12 | 57 | 77 | |

| Suspension | Differential to rear subframe | M12 | 70 | 95 | |

| Suspension | Differential to rear subframe | M14 | 128 | 174 | |

| Suspension | Rear suspension reinforcement to undercarriage | M12 | 57 | 77 | |

| Suspension | Rear suspension reinforcement to undercarriage (8.8 grade) | M8 | 15 | 21 | |

| Suspension | Rear suspension reinforcement to undercarriage (10.9 grade) | M8 | 22 | 30 | |

| Suspension | Wheel to wheel hub | 74 ± 7 | 100 ± 10 | ||

| Transmission | Clutch slave cylinder to transmission | 16 | 22 | ||

| Transmission | Clutch master cylinder to pedal cluster | 16 | 22 | ||

| Transmission | Fluid line to master cylinder or slave cylinder | 15 + 4 | 20 + 5 | ||

| Transmission | Clutch to flywheel (8.8 grade) | 18 | 24 | ||

| Transmission | Clutch to flywheel (10.9 grade) | 25 | 34 | ||

| Transmission | Transmission to engine | M8 Torx | 16 | 22 | |

| Transmission | Transmission to engine | M10 Torx | 32 | 43 | |

| Transmission | Transmission to engine | M12 Torx | 53 | 72 | |

| Transmission | Transmission drain or fill plug | 37 | 50 | ||

| Transmission | Back-up light switch to transmission | 15 | 20 | ||

| Transmission | Center bearing (driveshaft) to body | 15 | 21 | ||

| Transmission | Clamping sleeve (driveshaft) | 10 | 89 | ||

| Transmission | Driveshaft to final drive flange | M10 Ribbed | 59 | 80 | |

| Transmission | Driveshaft to final drive flange | M10 Compressed | 47 | 64 | |

| Transmission | Flex-disc (guibo) to driveshaft or transmission flange (8.8 grade) | M10 | 35 | 48 | |

| Transmission | Flex-disc (guibo) to driveshaft or transmission flange (10.9 grade) | M10 | 44 | 60 | |

| Transmission | Flex-disc (guibo) to driveshaft or transmission flange (12.9 grade) | M10 | 74 | 100 | |

| Transmission | Transmission / transfer case crossmember to chassis | M8 | 15 | 21 | |

| Transmission | Transfer case to transmission | M10 | 30 | 41 | |

| Transmission | Transmission output flange to output shaft (stage 1) | 140 | 190 | ||

| Transmission | Transmission output flange to output shaft (stage 2; after loosening) | 89 | 120 | ||

| Transmission | Guide sleeve to transmission | M6 | 10 | 89 | |

| Transmission | Rubber mount to transmission or bracket nut | M8 | 15 | 21 | |

| Transmission | Slave cylinder to transmission | 16 | 22 | ||

| Transmission | ATF drain plug to ATF sump (A5S 360R / A5S 390R) | M14 | 15 | 20 | |

| Transmission | ATF drain plug to ATF sump (A5S 325Z) | 26 | 35 | ||

| Transmission | ATF fill plug to ATF sump (A5S 360R / A5S 390R) | M14 | 15 | 20 | |

| Transmission | ATF fill plug to ATF sump (A5S 325Z) | 22 | 30 | ||

| Transmission | ATF sump to transmission (A5S 360R / A5S 390R) | M14 | 7 | 10 | |

| Transmission | ATF sump to transmission (A5S 325Z) | 4 | 6 | ||

| Transmission | Front suspension reinforcement to chassis | M10 | 30 | 42 | |

| Transmission | Torque converter to drive plate | M10 | 33 | 45 | |

| Transmission | Transmission support crossmember to chassis | 17 | 23 | ||

| Transmission | Transmission to engine (Torx-head with washer) | M8 | 15 | 21 | |

| Transmission | Transmission to engine (Torx-head with washer) | M10 | 31 | 42 | |

| Transmission | Transmission to engine (Torx-head with washer) | M12 | 53 | 72 | |

| Transmission | Shift cable clamping nut | 9 | 12 | ||

| Transmission | Center bearing to body | 15 | 21 | ||

| Transmission | Clamping sleeve | 10 | 89 | ||

| Transmission | Drive axle to differential flange | M10 Torx | 61 | 83 | |

| Transmission | Drive axle to differential flange (with locking teeth) | M10 | 71 | 96 | |

| Transmission | Drive axle to differential flange (with ribbed teeth) | M10 | 74 | 100 | |

| Transmission | Drive axle to differential flange (with ribbed teeth; silver ZNS) | M10 | 59 | 80 |

BMW 3 Series (E46): Service Manual: M3, 323i, 323Ci, 325i, 325Ci, 325xi, 328i, 328Ci, 330i, 330Ci, 330xi: Sedan, Coupe, Convertible, and Sport Wagon: 1999, 2000, 2001, 2002, 2003, 2004, 2005. (2005). Cambridge, MA: Bentley.

Ultimate BMW Wheel Spacer, Bolts, Studs Size Guide

For those of you that are researching wheels, spacers, bolts and stud kits you want to take a look at our BMW Wheel Thread and Bolt Pattern Guide. Getting the right hardware is critical as there is a minimum engagement length and number of turns required for each car. For 12×1.50mm bolts you need approximately 10mm of length or 6.5 turns. With 14×1.25 you need 12mm in length or 9.0 turns. 14×1.50 will require 12mm in length or 7.5 turns. If you don’t meed the minimum engagement, your studs or bolts will most likely fail prematurely.

❗Spacer requirements vary by car. Outside factors such as coilover perch clearance, brake caliper clearance, fender clearance and other factors may limit your hardware selection. We always recommend to start with the wheel first and test fit before you make a decision on getting hardware.

BMW Wheel Thread and Bolt Pattern Guide

| SERIES | YEAR | BOLT PATTERN | LUG SIZE (mm) | LUG TYPE | CENTER BORE (mm) |

|---|---|---|---|---|---|

| 1 Series | 2008+ | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| 2 Series | 2014+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| 3 Series | 1979-1991 | 4x120 | M12x1.5 | Conical Bolt | 57.10 |

| 3 Series | 1992-2013 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| 3 Series | 2014+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| 4 Series | 2014+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| 5 Series | 1975-1996 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| 5 Series | 1997-2010 | 5x120 | M12x1.5 | Conical Bolt | 74.10 |

| 5 Series | 2011+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| 6 Series | 1975-1988 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| 6 Series | 2010+ | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| 6 Series | 2011+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| 7 Series | 1975-1987 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| 7 Series | 2010+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| 8 Series | 1992+ | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| M3 | 1988-2013 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| M3 | 2014+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| M5 | 1985-1995 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| M5 | 1998-2003 | 5x120 | M12x1.5 | Conical Bolt | 74.10 |

| M5 | 2005-2010 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| M5 | 2011+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| M6 | 1983-2010 | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| M6 | 2011+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| Z8 | 2001+ | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| X3 | 2004-2010 | 5x120 | M14x1.5 | Conical Bolt | 72.56 |

| X3 | 2011+ | 5x120 | M14x1.25 | Conical Bolt | 72.56 |

| X5 | 2001-2005 | 5x120 | M14x1.5 | Conical Bolt | 74.10 |

| X5 | 2006-2013 | 5x120 | M14x1.25 | Conical Bolt | 74.10 |

| X5 | 2014+ | 5x120 | M14x1.25 | Conical Bolt | 74.10 |

| X6 | 2008+ | 5x120 | M15x1.5 | Conical Bolt | 74.10 F / 72.56 R |

| Z3 M | 1996+ | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

| Z4 M | 2006+ | 5x120 | M12x1.5 | Conical Bolt | 72.56 |

Spacers, Studs & Bolts Guide

| Thread Pitch | OEM Engagement Length (mm) | Spacer Size (mm) | Required Bolts (mm) | Required Studs (mm) |

|---|---|---|---|---|

| M12x1.5mm | 10 | 0 | 25 | 75 |

| M12x1.5mm | 10 | 3 | 28 | 75 |

| M12x1.5mm | 10 | 5 | 30 | 75 |

| M12x1.5mm | 10 | 12 | 38 | 75 |

| M12x1.5mm | 10 | 15 | 40 | 90 |

| M12x1.5mm | 10 | 20 | 45 | 90 |

| M12x1.5mm | 10 | 25 | 50 | 90 |

| M14x1.25 | 12 | 0 | 28 | 75 |

| M14x1.25 | 12 | 3 | 31 | 75 |

| M14x1.25 | 12 | 5 | 33 | 75 |

| M14x1.25 | 12 | 12 | 40 | 75 |

| M14x1.25 | 12 | 15 | 43 | 90 |

| M14x1.25 | 12 | 20 | 48 | 90 |

| M14x1.25 | 12 | 25 | 53 | 90 |

| M14x1.5 | 12 | 0 | 28 | 75 |

| M14x1.5 | 12 | 3 | 31 | 75 |

| M14x1.5 | 12 | 5 | 33 | 75 |

| M14x1.5 | 12 | 12 | 40 | 75 |

| M14x1.5 | 12 | 15 | 43 | 90 |

| M14x1.5 | 12 | 20 | 48 | 90 |

| M14x1.5 | 12 | 25 | 53 | 90 |

-

78mm M12x1.5mm Race Studs - Pure Bullet

$5.00 – $105.00Price range: $5.00 through $105.00-

82mm M12x1.5mm Race Studs - Hex Head

$6.00 – $130.00Price range: $6.00 through $130.00-

68mm M12x1.5mm Race Studs - Hex Head

$5.00 – $118.00Price range: $5.00 through $118.00-

90mm M12x1.5mm Race Studs - Hex Head

$6.00 – $137.00Price range: $6.00 through $137.00-

75mm M12x1.5mm Race Studs - Hex Head

$6.00 – $124.00Price range: $6.00 through $124.00-

-

-

-

-

-

-

#GRIDLIFE Time Attack at Streets of Willow

Check out the Time Attack at Streets of Willow! #GRIDLIFE Streets Special video that was made by Gears and Gasoline. If you’re not familiar with GRIDLIFE they throw some of the best event/festivals for the auto enthusiast community but they’re mostly done in the east coast – actually all of them. Until this.

They came out to Street of Willow to do a bracket style head to head time attack battle. Pretty much the same format as Formula DRIFT where you need to close the gap, but actually timed in seconds.

The video doesn’t tell the story that well, but I had a blast doing runs with Vinny in his E46 M3. (My twin) We basically were neck and neck most of the time. He ended up taking the W, but damn that adrenaline rush is something new.

You can also see Connie and Allison in the video doing some rollers at the end. Check it out!

Almost Crashing Into Vinny's E46 M3

GRIDLIFE Battle at Streets of Willow CCW going against Vinny Anatra and his E46 M3. This was our One More Time battle and my strategy was to let him go first so I can give him pressure. Coming down the front straight going into the skid pad, I late braked, but the car wouldn’t stop because of knock back on the Stoptech ST-40 so I had to veer off my line. I tried my best to stay with him, but he ended up taking the W. Super fun battle though!

Quick-Release Adjustable Front Splitter Brackets Install DIY

Here are the install DIY for our Quick-Release Adjustable Front Splitter Brackets and Front Race Splitter. You’re going to need to jack up the car and remove your bumper to do this install. The removal of the bumper support beam is also required. Models dating up to 2003 have the aluminum carrier and 2003.5 and up have the kevlar so make sure you check to see which one you have. This install will take about 1-2 hours. Everything is bolt-on and you just need basic tools. To get an idea of the bracket and splitter installation, first watch the quick-release demonstration video below.

⚠️ It is required to trim the front bumper in order to make clearance for the splitter brackets. Trimming will not be visible on the outside.

Tools required

- 13mm socket

- 10mm socket and wrench

- 8mm wrench

- 1/4″ drill bit and drill

- 5/32 allen key

- Marker

Quick-Release Adjustable Front Splitter Brackets Parts list

| Part No. | Part Name | Quantity |

|---|---|---|

| 1 | Steel Bumper Bracket | 2 |

| 2 | Steel Adjustment Bracket | 2 |

| 3 | Steel Feet w/ Pin | 2 |

| 4 | M6 20mm Serrated-Flange Hex Head Screws | 8 |

| 5 | M6 Nylon-Insert Flange Locknut | 12 |

| 6 | M6 18mm Hex Drive Flat Head Screw | 4 |

| 7 | M7 Hex Nut | 8 |

| 8 | 3/8″ 1.5″ OD Washer | 4 |

Race Splitter Parts List

| Part No. | Part Name | Quantity |

|---|---|---|

| 1 | Race Splitter | 1 |

| 2 | U-Channel (optional) | 1 |

| 3 | M6 12mm Hex Head Screw (included with U-Channel) | 3 |

| 4 | M6 12mm OD Washer (included with U-Channel) | 3 |

| 5 | M6 Nylon-Insert Locknut (included with U-Channel) | 3 |

| 6 | Splitter Guard (optional) | 1 |

Splitter bracket install directions

1. Remove front bumper.

2. Remove aluminum or kevlar carrier from bumper with 13mm socket.

3. Remove front undertray.

4. Install U-Channel with the supplied (3) M6 12mm Hex Head Screws, (3) M6 12mm OD Washers, and (3) M6 Nylon-Insert Locknuts. You will install using the existing 3 OEM front brace holes that connected to the under tray. Line up the 10mm nuts in the channel first and slowly position it into place. Insert the 10mm bolts through the top of the 3 OEM front brace holes.

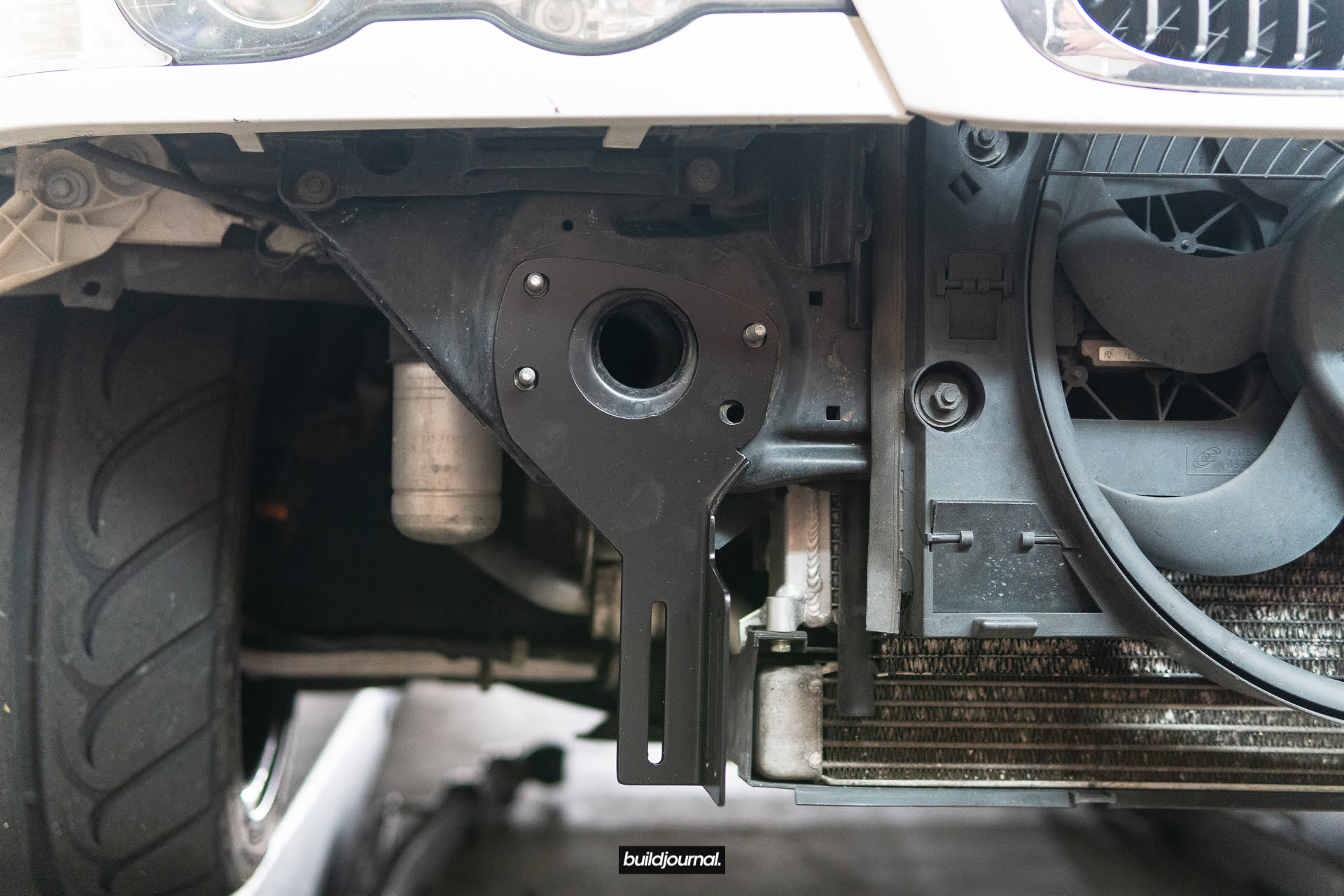

5. Install Steel Bumper Brackets on each side.

⚠️ For those that have aluminum bumper carriers, you must drill out the spot welds on the bumper shocks prior removing. There should be two spot welds on each side. After the spots welds are fully removed, you can remove each bumper shock.

6. Install Steel Adjustment Brackets on each side using (8) M6 16mm Serrated-Flange Hex Head Screws, (8) M6 Nylon-Insert Flange Locknuts, and (8) M6 18mm OD Washers. You can preset the height for now in reference to how it’s shown in the picture. You’re going to need to micro-adjust the height in the last step, but this should be a good preset for running the ACS lip and stock OEM bumper.

7. Install Aluminum Feet with (4) M6 20mm Serrated-Flange Hex Head Screws and (4) M6 Nylon-Insert Flange Locknuts. Apply hand tight.

8. Observe the 3 cutouts on the Buildjournal Race Splitter. These are cut inwards to sit flush against the U-Channel.

9. Reinstall the bumper carrier and install 13mm OEM nuts.

10. Slide the splitter into the U-Channel. Double check to make sure the splitter sits flush and back against the U-Channel.

11. Align the splitter in the middle and hold pressure against the back of the U-Channel. Carefully raise the splitter up against the aluminum feet and mark the drill locations using a marker.

12. Use the (4) M6 18mm Hex Drive Flat Head Screws, (4) M6 18mm OD Washers, and (4) M6 Nylon-Insert Flange Locknuts to install splitter onto Aluminum Feet.

13. Check the top and bottom of the splitter to see if seating is still in proper position all the way against the back of the U-Channel. Tighten down the feet to the splitter.

14. Adjust the Steel Adjustment Brackets to set your desired height and tighten everything down. Install your bumper back on.

PRO TIP: Since I have my radiator shrouds removed, I can disconnect the splitters from the engine bay, top down. This makes it a super easy and fast removal whenever I need to get on the trailer or doing an oil change.

⚠️ Additional Buildjournal Splitter Brace reinforcement for the Race Splitter is recommended to ensure stability during high-speeds. It is also critical to set the angle-of-attack (AOA) of the Race Splitter so there is not excessive downwards angle at high-speeds. We recommend slightly positive (facing upwards) AOA from neutral 0 degrees.

GRIDLIFE 2019 Streets of Willow CCW - 1:25.653

GRIDLIFE hosted their first ever event in the west coast for a head to head bracket elimination style track battle and I entered to see what it's about. The event is widely popular in the east coast due to the "festival" type of event that it organizes. It's basically a track day, but with car shows, music and food. If you ever been to Bimmerfest at Auto Club Speedway it's kind of like that vibe.

The morning consisted of 3 regular track sessions, however those that were in the competition had to set a qualifying lap time during those 3 sessions. The fastest of the bunch got to compete in the bracket finals. I went up against another E46 M3 and I ended up advancing. Next I faced Vinny Anatra, from Hoonigan, in his E46 M3 and it was such a rad experience. There's a competition element to the format so the energy is more intense than normal track days. It's almost like the first track day I've ever done where I'm nervous and just dosing off through the window as I sit on the hot pit waiting to go out. It was a refreshing experience. Something different than just a HPDE "time attack" track day.

We each got 2 runs and whoever takes 2 wins. Vinny led the first run and I ended up beating him. On the 2nd run, Vinny was in the chase and he ended up beating me. So it was 1 and 1 so we had to go One More Time. At the end Vinny ended up beating me, but the whole experience was such a thrill. I would do it again if they came back for another event. There's nothing like the feeling of going heads up with the entire track to ourselves and battling it out in a bumper to bumper fashion.